The passion reaches customers in returnable bottles.

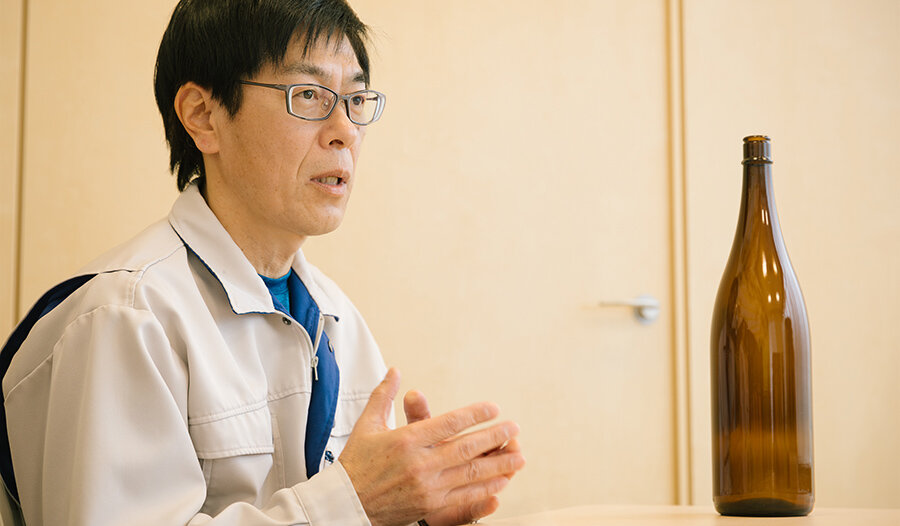

Inspectors safeguarding the quality of 1800ml bottles.

Their split-second judgments uphold quality.

As exemplified by the word "mottainai," the culture of reusing everyday items rather than throwing them away has been deeply rooted in Japan since ancient times. During the Edo period, there were businesses that collected waste paper and kimonos, as well as many craftsmen who repaired metal products and lacquerware.

At the beginning of the Meiji period, when the import of various Western alcoholic beverages began and glass bottles arrived in Japan, a business was born that bought and sold used bottles. This reuse culture spread further with the start of domestic glass bottle production in 1901 and the appearance of sake bottles in 1800ml bottles called "issho-bin." This was the prototype of the "reusable bottle" that would later be called "returnable bottles."

Returnable bottles are bottles that are collected, washed, and reused as products in their original glass form after use. They are said to have been used in Japan for over 100 years.

"In accordance with the policy of our previous president, who was mindful of the impact on the environment, Kirishima Shuzo still uses returnable bottles on its 1800ml bottle production line*."

This was shared by Mitsuhiro Yamashita from the Bottling Department.

At the time, 1800ml reportedly had a high reuse rate nationwide. With this background, Kirishima Shuzo also began using returnable bottles.

The Bottling Department is responsible for the process of packing shochu into bottles and packs, with different lines for different types of containers, but the line for 1800ml bottles is a bit special.

*Excluding some products such as Kichisuke

Using returnable bottles means the cleaning and inspection during bottling require more thoroughness than standard containers. After washing, the bottles are thoroughly checked for scratches and chips. This inspection is carried out using a strict system that includes an empty bottle inspection machine installed on the line and visual inspection by three inspectors.

Three inspectors, each responsible for inspecting the neck, body, and base of the bottles, keep a close eye on the bottles as they pass in front of a backlight. Approximately 160 bottles per minute. They must check the bottles that come flowing at that speed in an instant.

"You have to concentrate so hard you can't even blink, so eye drops to relieve eye strain are essential."

So says Riko Suehara, one of the inspectors.

Inspectors hold a special role within the Bottling Department that can only be filled by those who have undergone training and passed a test. It takes six months to a year of training to become a fully qualified inspector, and even among the many employees in the Bottling Department, only about 15*are certified as inspectors on the 1800ml bottle line.

*As of May 2024

"It is said that the human capacity for concentration is limited to 20 to 30 minutes, so we work in 20-minute shifts."

The concentration and patience required are like that of an athlete. When shown several samples of bottles with scratches, some were difficult for a layperson to spot. Yamashita, who is not an inspector, admitted with a wry smile, "Even I sometimes think, 'Where?!' and can't find it." Yet the inspectors instantly detect such minute scratches.

Suehara explains:

"As long as there is a possibility that hands or mouths may come into contact with the bottle, we need to make various assumptions and guarantee safety to our customers. This is no different from the passion that manufacturers have for the quality of shochu."

I asked a simple question: Why not increase the number of inspection machines?

"Machines can 'detect' whether there are scratches or not, but they cannot 'judge' whether it is OK or not," Yamashita replies.

These bottles have been on the market at one time, and there are bound to be some scratches. When using returnable bottles, it is important to judge whether the scratches will lead to damage or whether they affect the appearance of the product, but this is currently difficult for machines to do.

"With the recent advancements in AI and camera performance, I feel that our challenge going forward will be to find ways to further improve our inspection system."

Shochu production is only possible thanks to the blessings of nature.

That is why we must continue to seek out new ways to make shochu that have a minimal impact on the environment. Even as methods evolve with the times, the philosophy of ensuring that customers can enjoy delicious shochu with peace of mind will remain unchanged.

It is the rigorous inspection system, upheld by the human eye of inspectors, that underpins Kirishima Shuzo's quality.

*Please refrain from sharing alcohol-related information with those under 20 years old.

- From hashtags

Interesting articlesSearch for