The Blessings Nurtured by Kyushu’s Shirasu Plateau

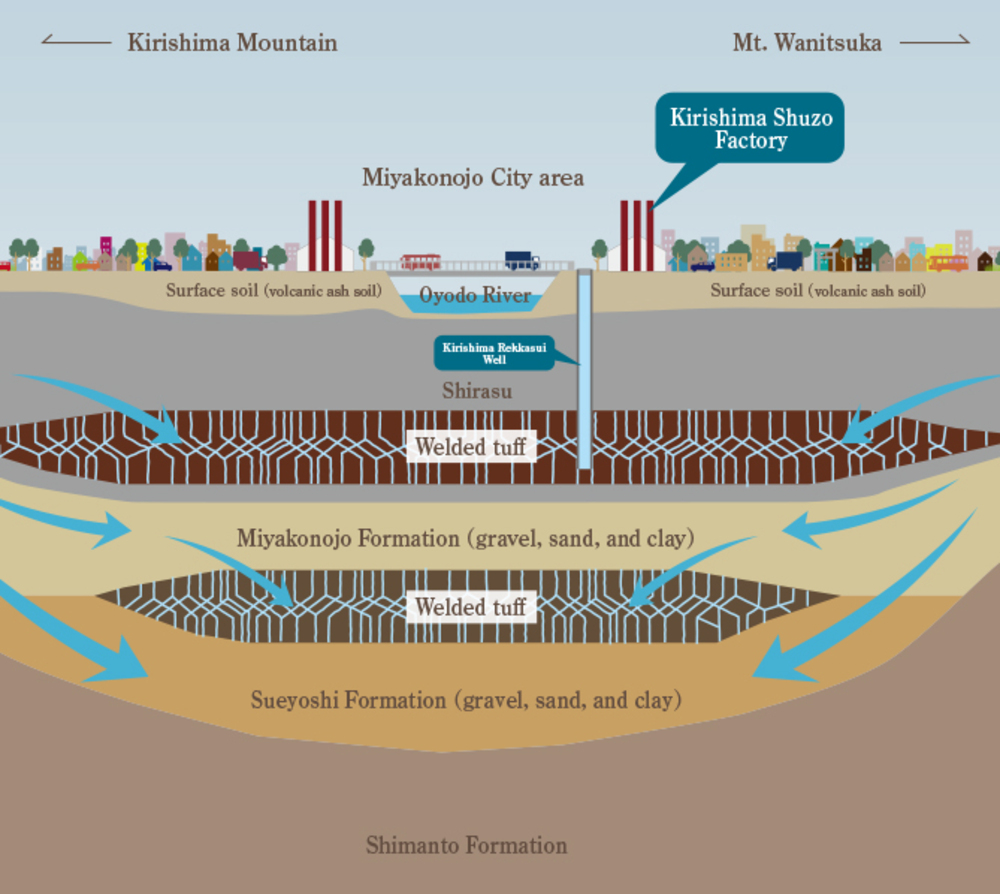

The production of delicious shochu is only possible thanks to the blessings of the local area. Kyushu's Shirasu Plateau, with its volcanic ash soil and excellent drainage, is ideal for growing sweet potatoes. We Kirishima Shuzo use 100% Kyushu-grown sweet potatoes in our production. This passion for fresh sweet potatoes allows us to create shochu that is rich in flavor, free from any impurities.