Made with Carefully Selected Sweet Potatoes

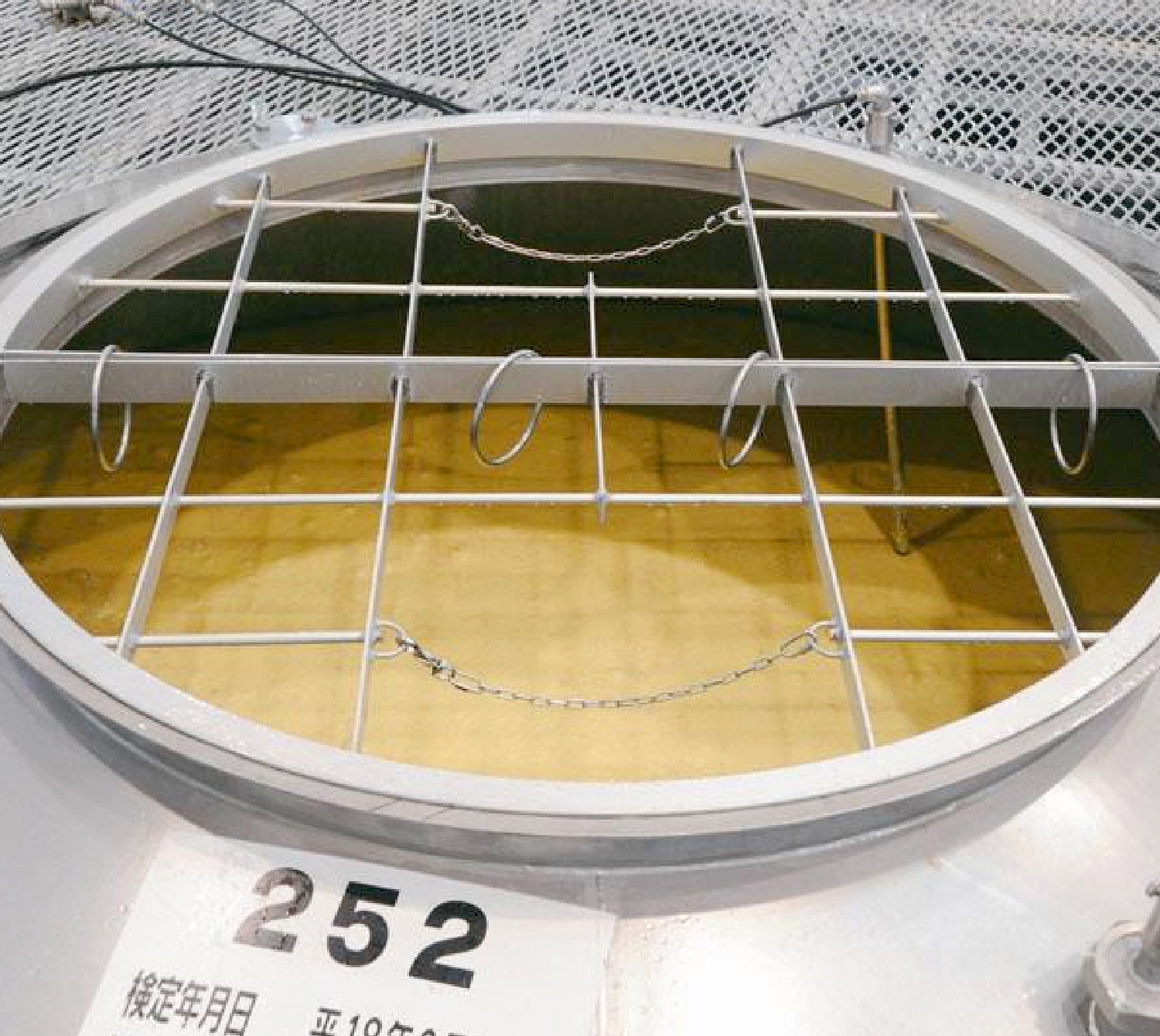

Each factory processes approximately 80 tons of sweet potatoes per day, amounting to a total of around 400 tons across five factories. During the harvest season from August to December, fresh sweet potatoes are delivered daily.