In line with the harvest season, farmers select seed sweet potatoes for growing next year’s sweet potato seedlings. Good seed sweet potatoes are those without any damage or disease, and have a good shape. These are stored in appropriate conditions until early spring, when seedling production begins.

The Life Cycle of Sweet Potatoes

Great Taste is Cyclical.

Shochu Production with the Future in Mind

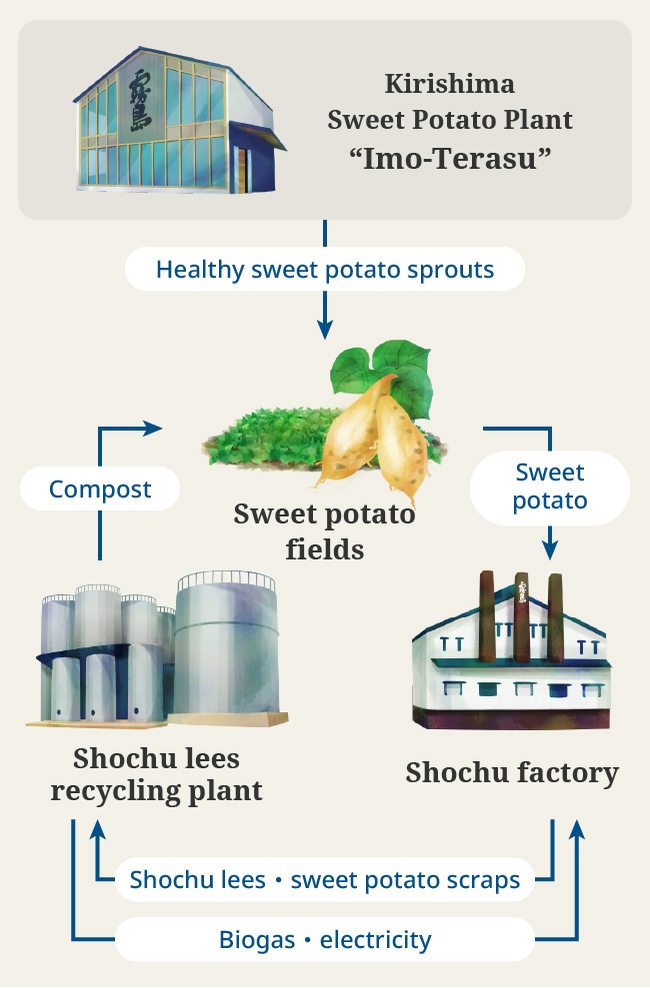

Sweet potato seedlings, planted in spring, spread their vines and leaves across the fields, absorbing the sun's energy. After they mature, the sweet potatoes are transformed into shochu, becoming a source of vitality for people. The byproducts of the production process—such as shochu lees and sweet potato scraps—are converted into energy and compost for both the factory and the local community. Through the cultivation of healthy sweet potato seedlings in Imo-Terasu, we support local farmers while working towards building a sustainable, circular shochu production system.

Shochu Production Starts with

Sweet Potato Cultivation

Seed sweet potatoes sprout in a warm environment and produce several vines (seedlings). It takes over 40 days for these to grow into seedlings in greenhouse. Depending on the variety and cultivation method, farmers harvest seedlings 5 to 6 times.

Farmers plant the seedlings in the field once the ground surface warms up in spring. Strong, sturdy seedlings with thick stems are planted into well-drained fields with good airflow.

Kirishima Sweet Potato Plant

“Imo-Terasu”

Initiatives

In recent years, sweet potato foot rot disease has been increasingly affecting sweet potatoes used in shochu production. To ensure that farmers can grow their crops safely, Kirishima Shuzo provides support starting from the seedling stage.

Cultivating and supplying healthy seedlings

Sweet potato foot rot disease poses a risk of infection at all stages of sweet potato production. To mitigate this risk, Imo-Terasu cultivates healthy seedlings by growing the shoot tips (apical parts) of seedlings that are free from detectable fungi and viruses, supplying these seedlings to farmers.

Research and development of sweet potatoes

We are exploring the potential of sweet potatoes by developing varieties suitable for direct seeding to reduce labor and those that can create unique flavors of shochu. At Imo-Terasu, we focus on understanding growing environments, improving cultivation efficiency, and developing new varieties to ensure stable production and drive innovation.

The Harvested Sweet Potatoes are

Transported to the Factory

The sweet potatoes used at Kirishima Shuzo are cultivated across 3,000 hectares of land—equivalent to 640 Tokyo Domes. Harvested from August to December, they are promptly transported to the shochu manufacturing plant to preserve their freshness.

Each factory processes approximately 80 tons of sweet potatoes per day, amounting to a total of around 400 tons across five factories. During the harvest season from August to December, the sweet potatoes are hand-selected with care to ensure the best possible shochu.

Shochu Manufacturing

Byproducts

The sweet potato scraps removed during sorting and the shochu lees produced after distillation are fermented into methane using methane bacteria and converted into biogas. The collected biogas is then used as fuel for boilers and power generation in the manufacturing process.

The byproducts remaining after methane fermentation are separated into solid and liquid forms. The solid material is repurposed as compost for agricultural products, including sweet potatoes, and is returned to the soil of southern Kyushu. The sweet potatoes cultivated using this compost subsequently serve as a key ingredient in the production of great-tasting shochu.

Sweet potatoes are

cultivated with care by farmers.

By using them with no waste,

we aim to produce shochu sustainably and delicious.