CO₂ Emissions Reduction Activities

We are working to reduce our businesses’ CO₂ emissions.

Energy Conservation Initiatives

(1) Using renewable energy

Shochu lees and sweet potato scraps discharged during production ferment into methane, and the extracted biogas (methane gas) is used as fuel for the shochu production boilers. By using the renewable energy of biogas, we are reducing our fossil fuel (city gas) usage.

(2) Effective use of factory exhaust heat

By using hot wastewater discharged during production in our boilers, we’re reducing our fossil fuel (city gas) usage. The water is used to clean factory equipment and for heating, helping the factory reduce energy consumption.

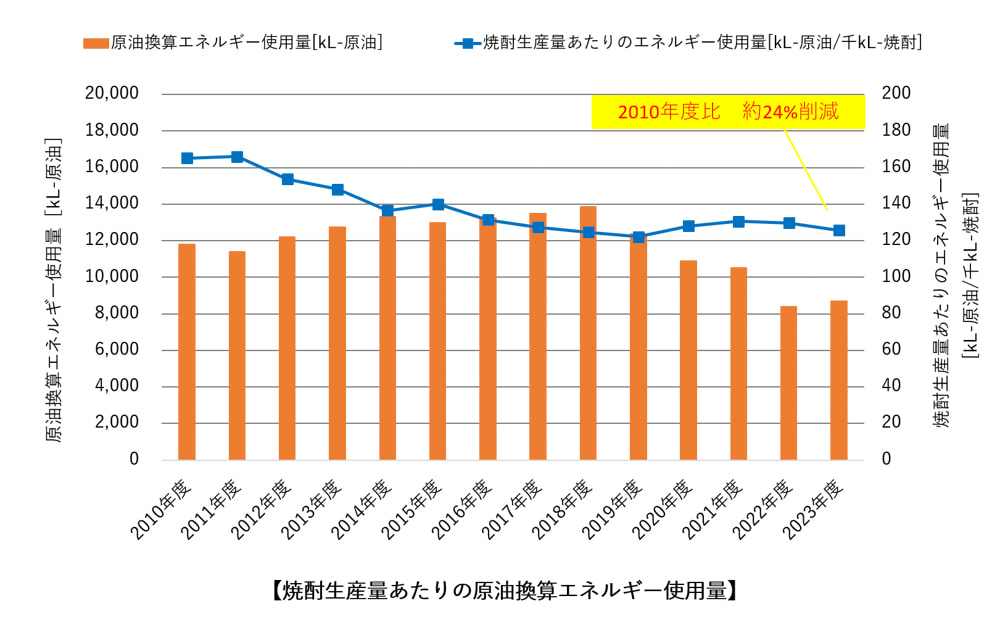

These initiatives have helped us reduce our energy consumption per unit*1 , as we used 24% less energy in FY2023 compared to FY2010.

In 2015 Kirishima Shuzo won Energy Conservation Grand Prize “Best Practice Category, Agency for Natural Resources and Energy Commissioner's Award (Industrial sector)”.

- The amount of energy used per unit of shochu production

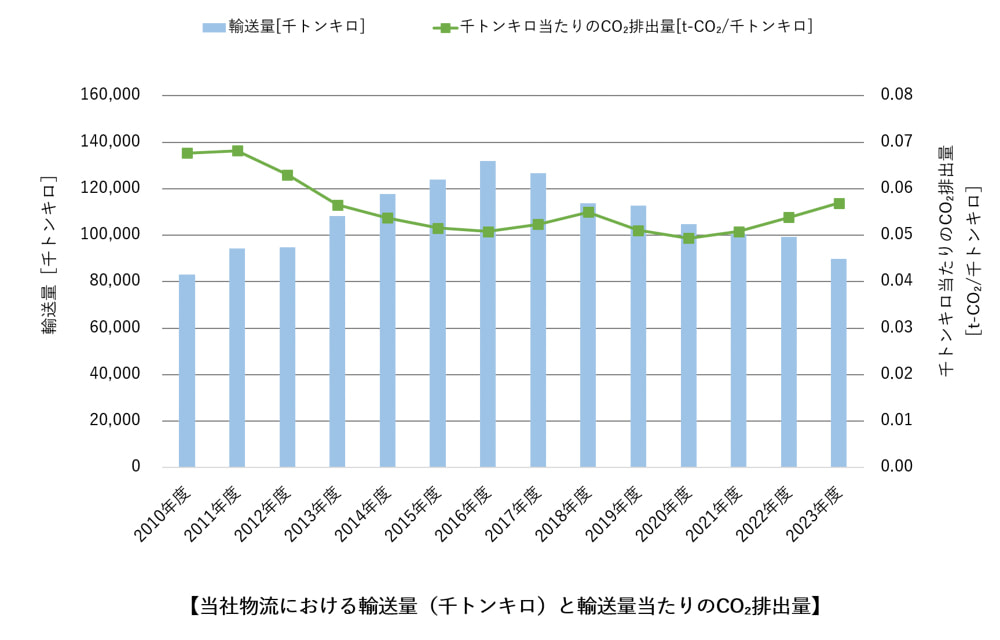

Logistics Initiatives

(1) Setting up distribution centers

Previously, we transported products from headquarters to destinations by mixed loading trucks, but we have switched to delivering them from our own 9 distribution centers across the country (in Miyazaki, Fukuoka, Okayama, Osaka, Aichi, Tokyo, Chiba, Miyagi, and Hokkaido). When shipping products from these distribution centers to destinations, we also use cooperative delivery*2 in some cases.

(2) Shifting to railway and marine transport

Most of our products used to be transported to our distribution centers by truck. To help reduce CO₂ emissions during transport, we have implemented a modal shift*3 to ship them via railway containers and by marine instead.

In 2016, we got the "Eco Rail Mark"*4certification.

In 2022, we have switched all transport outside of Kyushu to using railway containers or ships.

(3) Increasing truck sizes and loading efficiency

We’re working to increase transport efficiency by using larger trucks and increasing their loading efficiency.

(4) Reducing the CO₂ emitted when transporting raw materials

We use 100% Kyushu-grown sweet potatoes as our raw materials, and by increasing the amount of rice grown locally in Miyazaki, we’re reducing the CO₂ emitted during the transportation of them.

- Cooperative delivery: Delivering freight from multiple companies together. This increases the loading rate and improves transportation efficiency.

- Modal shift: Switching transport from trucks that have high CO₂ emissions to lower emission modes as railway and ships.

- Eco Rail Mark: An environmental label given to companies and products that are working to reduce CO₂ emissions through rail freight transport.

Resources Conservation Initiatives

The 900ml and 720ml bottles are stocked in bulk packaging to reduce the amount of cardboard used.

We are implementing Life Cycle Assessment (LCA) to determine the environmental impact (CO₂ emissions) throughout our products’ life cycles, from the procurement of raw materials to production, distribution and disposal.