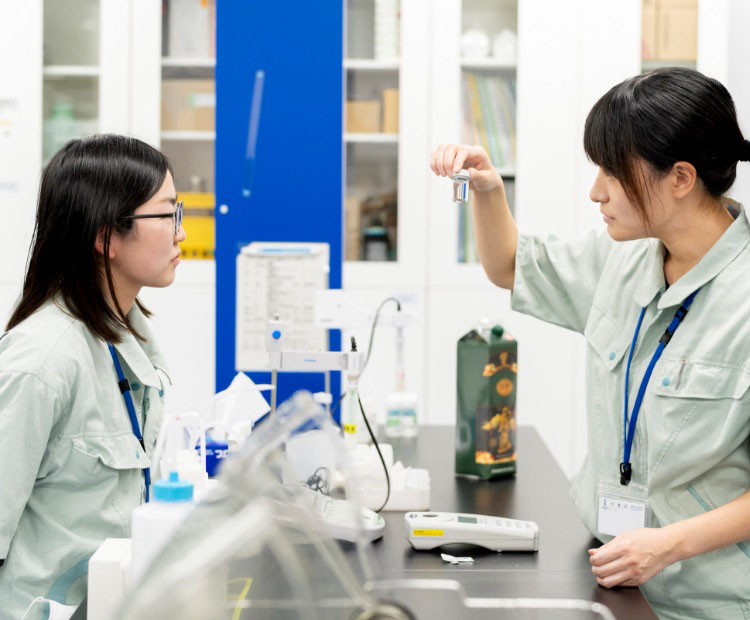

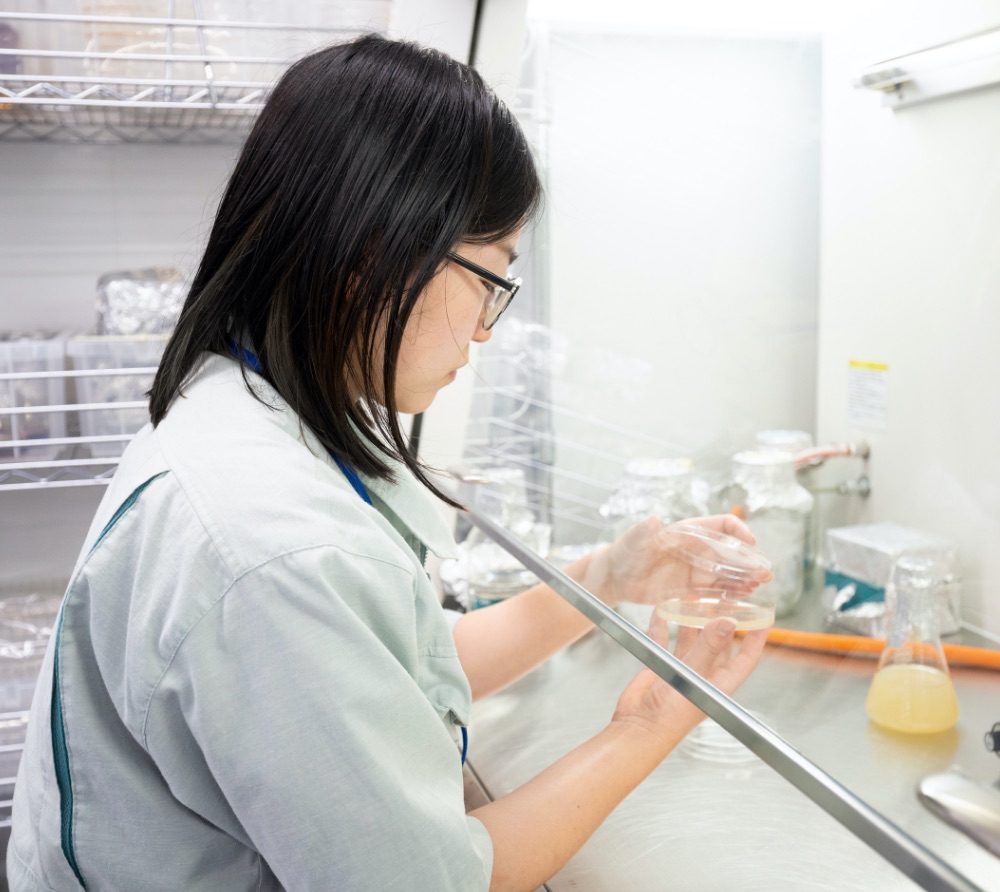

Ingredient screenings

Screenings check our raw materials (sweet potatoes and rice) for their origin, variety, color, shape, and for the presence of disease and damage. We also regularly conduct both in-house and external analyses, such as pesticide residue testing, to ensure safety. Our system can even do raw material safety checks based on cultivation records.